Laminated automotive glass

|

|

|

|

Laminated automotive glass request worldwide has increased in the past few years, enlarging the use of safety and acoustic glass in different and further fields than before. Iocco has seized this opportunity and constantly updates the range of possible engineering solutions to offer to automotive glass makers accordingly. (http://www.bodyshopbusiness.com/acoustic-laminates-market-continues-grow-automotive-industry/)

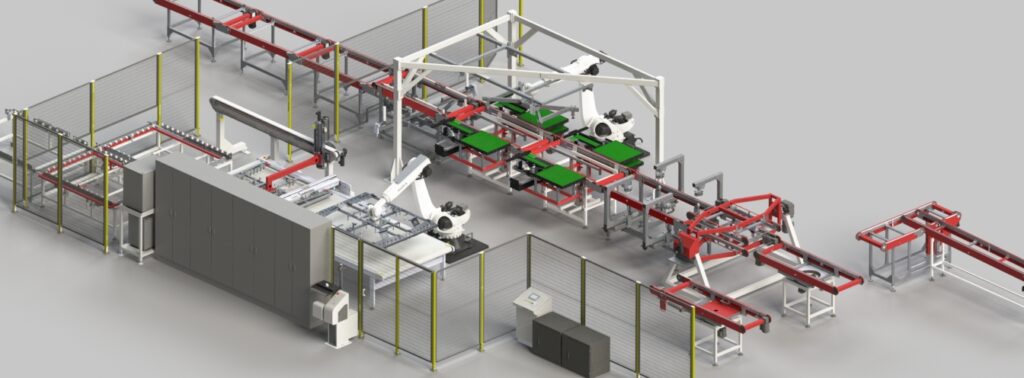

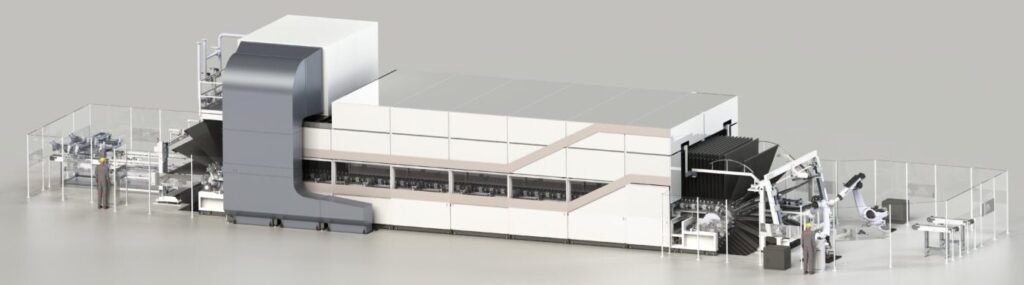

The extensive expertise our Company in Laminated automotive glass provides ranges from the single machine (such as the Vinyl unwinding machine) up to more complex lines (such as Assembly lines, bag furnace, on line application of components, Autoclave lines, PVB trimming, Inspection Lines on windshield, sunroof, sidelight, with automatic unloading and packaging system). This in order to ensure the best process improvement for our clients, guaranteeing the most customizable layout integration in line with safety regulations.

Iocco is an integrator of the main vision systems, ensuring the highest quality standards to the glass inspection process. Of course, the solutions we provide can be customized thus our Customers throughout the project phases.

Automatic_PVB_assembly_line The extensive expertise IOCCO Company provides ranges from single assembly machine to complete line, Laminated-automotive-glass- processing.

Automatic_PVB_assembly_line The extensive expertise IOCCO Company provides ranges from single assembly machine to complete line, Laminated-automotive-glass- processing.

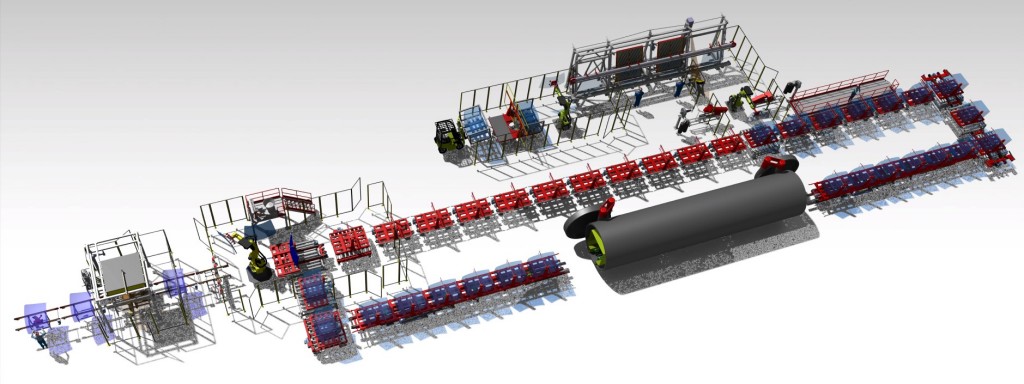

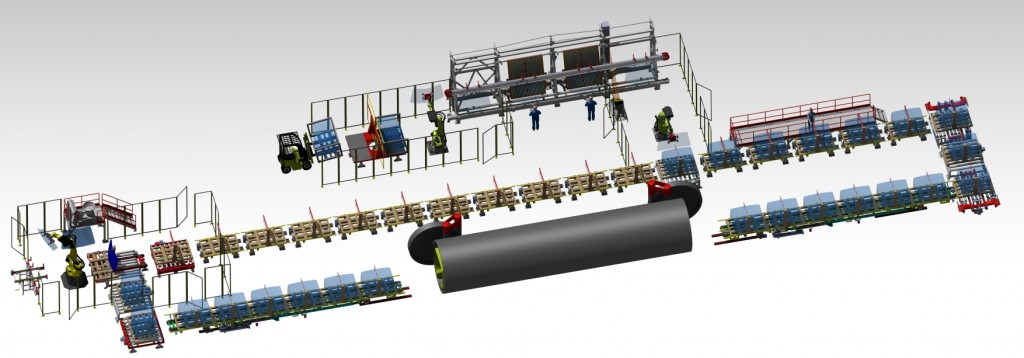

In the meantime PVB Pre-Processing – Trimming and Lay Up phases take place to unwind and accumulate vinyl interlayer. This is subsequently stretched to better adhere to glass, then it is cut, stored on trays and handled through an automatic tray feeding system to ease Assembly the PVB/Glass by the operators in the assembly room. The Assembly can be performed either automatically or semi-automatically.

In the meantime PVB Pre-Processing – Trimming and Lay Up phases take place to unwind and accumulate vinyl interlayer. This is subsequently stretched to better adhere to glass, then it is cut, stored on trays and handled through an automatic tray feeding system to ease Assembly the PVB/Glass by the operators in the assembly room. The Assembly can be performed either automatically or semi-automatically.

At the exit of the Autoclave, laminated glass undergoes PVB trimming operation and, after final washing, it enters in the Final Inspection Line, consisting in both visual and optical checks. Iocco is able to integrate multiple optical Vision Systems.

At the exit of the Autoclave, laminated glass undergoes PVB trimming operation and, after final washing, it enters in the Final Inspection Line, consisting in both visual and optical checks. Iocco is able to integrate multiple optical Vision Systems.