Float bath furnaces

Float process is the established technique to produce glass from the specific combination of raw materials such as soda and ash with recycled glass (cullet), melted into the furnace at approximately 1500°C. The molten glass coming out of the furnace is then delivered smoothly and continuously to the float bath, where tin allows the uniform thickness of the glass ribbon, making it solid. While moving smoothly on rolling conveyors the glass ribbon is further cooled through the annealing lehr, allowing the perfect flatness and solidity.Finally glass is cut into jumbo size sheets, before being stacked for transportation or other production phases.

There are various detection inspections on glass to ensure the best optical quality in each phase of the process.

Originally the glass produced was 6mm thick, but now it is possible to vary the thickness of glass from 0,4 mm to 25 mm, modulating the speed of glass exiting the bath.

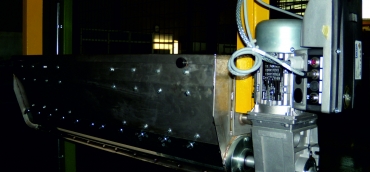

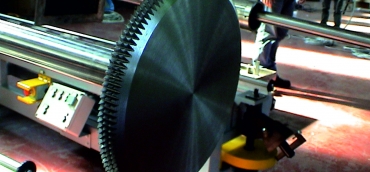

Iocco designs and supplies equipment fully integrated on Float bath furnaces process in the cold area with maintenance cold repair and machine construction.Expertise, competitiveness and applied technology guarantee the reliability of our installations.

PRODUCT RANGE

- Ancillary Equipment in hot zone

- Cold end equipment

- Storage System: AUTOMATIC STORAGE SYSTEM/END CAPS PACKING AREA

Expertise, competitiveness and applied technology guarantee the reliability of our installations.

HOW WE WORK

- Engineering Consulting

- Feasibility Study

- Mechanical, Electrical and Automation Design

- Machine Construction

- Mechanical Assembly

- Electrical Systems

- Software Development

- Installation and Training

- Manuals and Technical Documentation

- Certification in compliance with the European Laws

- Support, After-sale Service and Spare Parts

Contact Us

RECENT POSTS

IOCCO at China Glass 2024

"Discover how to produce Automotive Glass with Industry 5.0" meet IOCCO at 33rd China Glass...

IOCCO at China Glass 2024

"Discover how to produce Automotive Glass with Industry 5.0" meet IOCCO at 33rd China Glass...  Best wishes for happy Easter

May this beautiful spring bring you the greatest feelings of gratitude, love, compassion, hope and...

Best wishes for happy Easter

May this beautiful spring bring you the greatest feelings of gratitude, love, compassion, hope and...  IOCCO’s new Innovation Center is now operational

We are proud to announce the new opening on time of the IOCCO innovation center...

IOCCO’s new Innovation Center is now operational

We are proud to announce the new opening on time of the IOCCO innovation center...  Merry Christmas & Happy New Year to our clients and partners!

Other motivating challenges await us and our partners for the next year 2024.We are going...

Merry Christmas & Happy New Year to our clients and partners!

Other motivating challenges await us and our partners for the next year 2024.We are going...  Asianglass magazine talks about IOCCO technology

Push the button to read the magazine Asianglass magazine

Asianglass magazine talks about IOCCO technology

Push the button to read the magazine Asianglass magazine  American automotive glass makers select IOCCO technology

IOCCO recently made inroads into the American market with its advanced lamination tech for ultra-thin...

American automotive glass makers select IOCCO technology

IOCCO recently made inroads into the American market with its advanced lamination tech for ultra-thin...  SUMMER HOLIDAYS

IOCCO premises are going to be closed for summer break from August 12th to...

SUMMER HOLIDAYS

IOCCO premises are going to be closed for summer break from August 12th to...  IOCCO a constant Official System Partner of KUKA robotics

Kuka industrial robots to deliver formally the award to their Official System Partner 2023. IOCCO received...

IOCCO a constant Official System Partner of KUKA robotics

Kuka industrial robots to deliver formally the award to their Official System Partner 2023. IOCCO received...  IL POSTO GIUSTO

IOCCO was selected by RAI (national television) to discuss about the latest evolutions in automotive...

IL POSTO GIUSTO

IOCCO was selected by RAI (national television) to discuss about the latest evolutions in automotive...  Automotive Glass Technology: IOCCO explains today’s industry developments

IOCCO recently explained to E-Tech Europe attendees how automotive in a constant flux respecting developments...

Automotive Glass Technology: IOCCO explains today’s industry developments

IOCCO recently explained to E-Tech Europe attendees how automotive in a constant flux respecting developments...