Continuous R&D activity to be the first in the worldwide market

The world market is showing strong interest in the latest developments in IOCCO’s automotive glass lamination technology. Several installations in China, Europe, Mexico, North and South America in recent years confirm the growing trend towards the level of automation and control required to produce the latest generation of automotive glass to the high quality standards demanded by car manufacturers and the market. The automotive sector has embraced ultra-thin multilayer glass, including PDLC (Polymer Dispersed Liquid Crystal), PVB, SPD and XIR technologies.

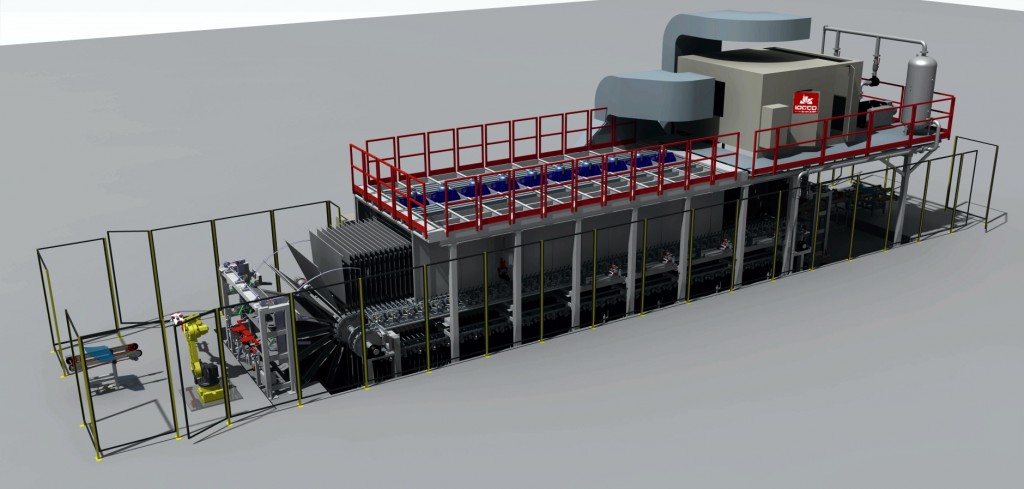

The production process phases most relevant in respect of technological production innovation are those of assembly and pre-lamination (namely, the de-airing process). Here’s why the R&D team at IOCCO has continuously developed solutions in line with these trends since 2012 – placing highly productive assembly and pre-lamination systems on the market which are unique worldwide. These allow for precise assembly phases and the subsequent phase of air extraction inside the laminate as well as the fusion and encapsulation of these technological interlayers.

The production process phases most relevant in respect of technological production innovation are those of assembly and pre-lamination (namely, the de-airing process). Here’s why the R&D team at IOCCO has continuously developed solutions in line with these trends since 2012 – placing highly productive assembly and pre-lamination systems on the market which are unique worldwide. These allow for precise assembly phases and the subsequent phase of air extraction inside the laminate as well as the fusion and encapsulation of these technological interlayers.

To date this system can produce windshields, side windows and sunroofs with production rates of up to 18 seconds per glass. Thanks to advanced sensors and intelligent software the plant is able to calculate the correct production parameters while tracing the technological process for each particular product and changing set-up in the event of unforeseen anomalies.

In accordance with their specific requirements and considering what biggest worldwide glass makers need, the qualified IOCCO Team – together with international partnerships – performed a reengineering of the traditional vacuum bag furnace adopting deairing process to which the automotive laminated glass are subjected to.

The final goal was to define 2 standard solutions for windshields and sun roof and 2 standard solutions for sidelights and backlites, modular and highly performing, having reasonable costs and a financial return of investment in about 48 months (24 hours per day). Today said solutions have been finalized and put into operations at the plants of our customers.

The final goal was to define 2 standard solutions for windshields and sun roof and 2 standard solutions for sidelights and backlites, modular and highly performing, having reasonable costs and a financial return of investment in about 48 months (24 hours per day). Today said solutions have been finalized and put into operations at the plants of our customers.

As TOP configuration, our vacuum bag furnaces include the tracking production data up to single glass, by the light of current requirements of primary worldwide car manufacturers.

All our solutions allow our customers, through sustainable investments, to increase their production in accordance with the performances agreed in the original request.

The main advantage of the vacuum bag furnace is to produce in full automatic way different kinds of glass, even  having complex and asymmetric shapes, and avoiding heavy interventions for change-overs.

having complex and asymmetric shapes, and avoiding heavy interventions for change-overs.

During the design and the fabrication particular attention has been dedicated to choosing and checking the installed commercial parts: in fact, all the components making part of the furnace are supplied by global companies, leaders in their specific field.

Thanks to the complete redesign, all maintenances prove to be small and simple to do.

As for accessories of the vacuum bag furnaces, IOCCO is also able to provide both low-vacuum checking systems and different loading and unloading equipment.

Vacuum bag furnace for sidelites & Backlites

deairing VACUUM BAG IOCCO Model: 300/SL/M Model: 300/SL/A

|

Vacuum bag furnace for windshield and sun roof

deairing VACUUM BAG IOCCO Model: 400/WS/M Model: 400/WS/A Vacuum channel ring furnace for windshield & sun roof

deairing VACUUM RING IOCCO (green snake) Model: 200/WSL/MR Vacuum box de-airing furnace to process in R&D DPT Hi-Tech Windshields, sun roof & sidelites

deairing VACUUM BOX IOCCO Model: Crystal 200/WSL/MR |