The new production unit composed by three spans, is optimized to realize up to three de-Airing Bag Furnaces simultaneously.

This growth enables the company to manage different big projects like complete lines for AVO or automatic lamination process for automotive glass and deairing bag furnaces which needs considerable space for the construction.

The space available inside separate locations, assure confidentiality for each project even for different customers contemporarily.

The Bag Furnace solution for a flexible production of laminated automotive glass.

Automotive glass industry requires more and more dynamic processes able to optimize change over to other glass models then to achieve reduction of production costs.

The lamination process in automotive glass industry is a bottle neck with conventional processes; also for this reason most of automotive glass makers are adopting our innovative de-airing bag furnace systems which allow model changes without any interruption of the process, obtaining a flexible production like never done before in automotive glass industry.

IOCCO’s R&D updated the previous de-airing bag furnaces in order to reach the first de-airing system in the world able to process Windshields, Sidelights glass and Sunroofs produced with ULTRA-THIN glass and multilayers as PVB-PDLC-SPD-XIR.

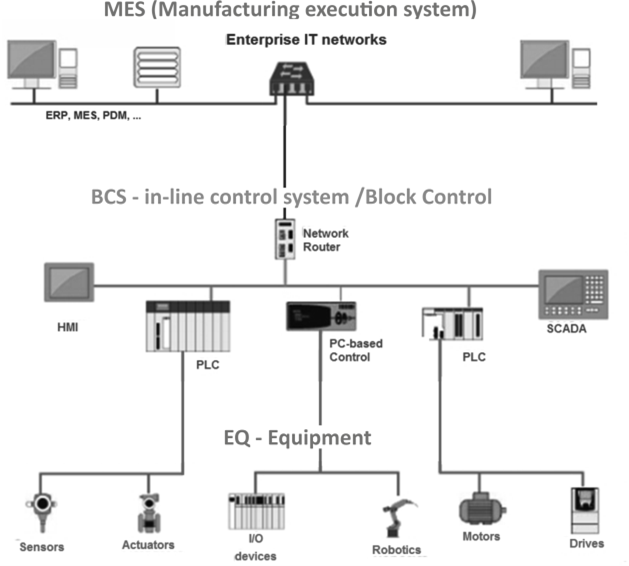

The automation & control section has been completely redesigned with numerous implementations; now the new system allows easy management (user friendly) in the face of a more complex software that manages the process.

The monitoring system allows to all the process phasis, vacuum values and temperatures on each produced glass thus to react to possible anomalies to guarantee continuous and quality production.

A good process control is the basis of competitiveness, both based on product quality and production capacity.

Fundamental is the understanding and managing the progress of the process data from the field.

The TEAM IOCCO has developed the ability to select and process only its own data with the continuous implementation of a structural software standard that includes all the installed devices.

Particular attention is paid to continuous information and training on the new systems offered by the market both in terms of sensors and actuators and PLC, Robot, Vision, human/machine interface (HMI) and PC-based systems.

Moreover, the remote connection enables IOCCO technicians to intervene in case of necessity, wherever the machine is located in the world, guaranteeing immediate assistance.

The system to collect production data helps the use and predicts the maintenance assuring a constant production running, with a result of a prompt aftersales service, also by means of augmented reality systems.