The first de-airing system in the world, able to process Windshields, Sidelights glass and Sunroofs produced with ULTRA-THIN glass and multilayers, as PVB-PDLC-SPD-XIR

Flexible productions, which allow model changes without any interruption of the process.

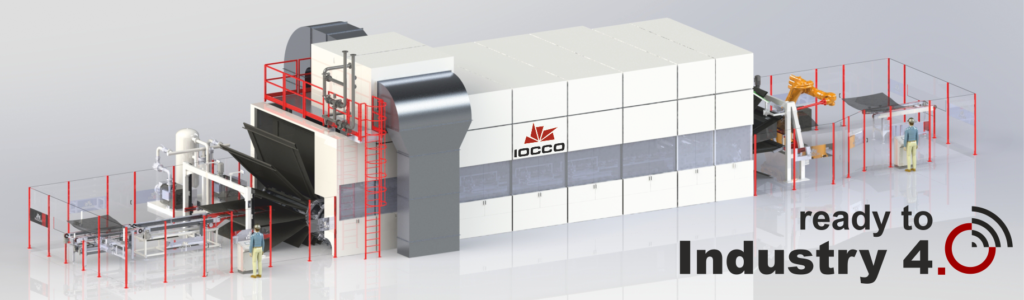

An important IOCCO’s contribution in the manufacture of systems for the air extraction during the lamination of windscreens, laminated sidelights and sunroofs is the notable improvement for both concept and fabrication of vacuum bag furnaces.

In fact, recently the R&D of IOCCO has conceived a new furnace that represents the evolution of those ones built and installed in the past.

Thanks to said evolution, in its various configurations the new vacuum bag furnace allows to:

- Process windscreens, laminated sidelights glass and sunroofs as well made of ultrathin glass and multilayers including PVB-PDLC-SPD-XIR

- Monitor all the process phasis, vacuum values and temperatures on each produced glass

- React to possible anomalies to guarantee continuous and quality production

- Reduce operating costs

- Manage and monitor production/process data in compliance with Industry 4.0

This new version arises from two fundamental factors:

- The first one is represented by the guidelines of the various government bodies on issues such as energy efficiency, emission reduction, innovation as well as being in line with the Industry 4.0 philosophy (fundable)

- The second one comes from the growing market trend of main Car Makers for the increased demand of laminated roofs and sidelights that are ever lighter, safer, complex in shape and with innovative technologies, and this in addition to windscreens increasingly equipped with ADAS systems.

- Flexible productions, which allow model changes without any interruption of the process.

Hence the idea to develop a single system capable of responding to these fundamental trends.

Innovative is the new aesthetic line that makes the vacuum bag furnace more elegant, refined and – let’s face it – better shows Italian Style.

The automation & control section has been completely redesigned with numerous implementations; now the new system allows easy management (user friendly) in the face of a more complex software that manages the process.

In this new version, the system is able to understand any thermodynamic anomalies, then to stabilize the process according to the new parameters, thus allowing a production continuity up to its total recovery.

The application of a new thermoventilation system has allowed the whole system to contain its dimensions in height, so that it can be installed even in the buildings where up to now it wasn’t possible.It should be noted that this new system involves significant energy savings, allowing for the first time to manage the real transfer of energy in accordance with the data suggested from the interlayer suppliers.

Another important advantage is the possibility to install an additional module for energy recovery which, together with the use of dedicated inverters and more performing insulation, as well as further implementations, have made possible to drastically reduce operating costs to the benefit of the processed products.

For details contact us

more information: https://www.ioccogroup.com/deairing-process/